what are the materials of spiral flute tap

Spiral flute taps are essential tools used in the manufacturing industry for creating internal threads in metal materials. These taps are designed with a spiral flute that helps to evacuate chips and debris from the hole being tapped, allowing for smoother and more efficient threading. The materials used in the construction of spiral flute taps play a crucial role in determining their performance and durability.

One of the most common materials used for spiral flute taps is steel. Steel is a versatile and durable material that is well-suited for the demanding conditions of tapping operations. There are several types of steel that are commonly used in the manufacturing of spiral flute taps, each with its own unique properties and advantages.

High-speed steel (HSS) is a popular choice for spiral flute taps due to its excellent wear resistance and toughness. HSS taps are capable of withstanding high temperatures and cutting speeds, making them ideal for use in a wide range of materials, including stainless steel, aluminum, and other alloys. HSS taps are also relatively easy to sharpen, allowing for extended tool life and cost savings over time.

Another type of steel commonly used in the construction of spiral flute taps is cobalt steel. Cobalt steel taps are made with a higher percentage of cobalt, which enhances their hardness and heat resistance. This makes cobalt steel taps well-suited for tapping hard materials such as titanium, Inconel, and other high-temperature alloys. Cobalt steel taps are also less prone to chipping and breaking, making them a reliable choice for demanding machining applications.

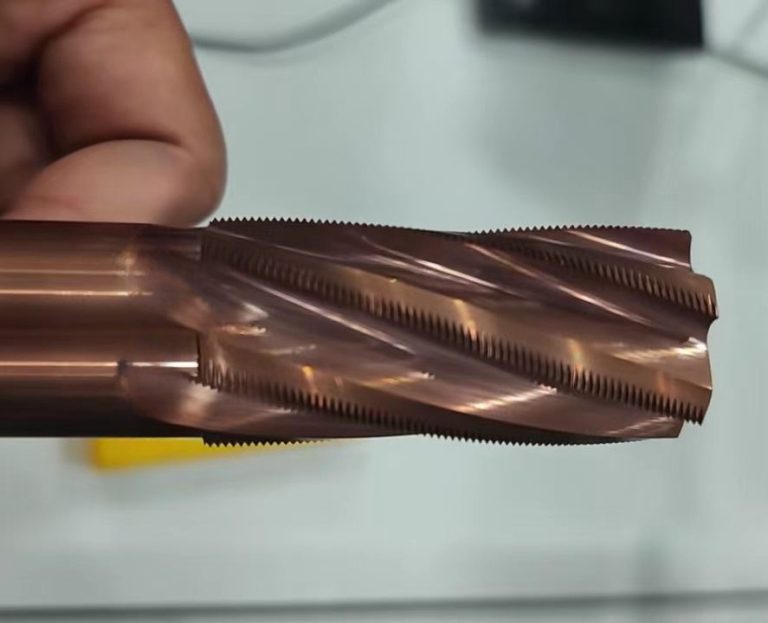

Carbide is another material that is sometimes used in the construction of spiral flute taps. Carbide taps are extremely hard and wear-resistant, making them ideal for tapping abrasive materials such as cast iron and hardened steel. Carbide taps are also capable of maintaining their cutting edges for longer periods, reducing the need for frequent tool changes and increasing productivity.

The coating applied to the tap can also impact its performance and longevity. Titanium nitride (TiN) and titanium carbonitride (TiCN) are two common coatings used on spiral flute taps to improve their wear resistance and lubricity. These coatings help to reduce friction and heat buildup during the tapping process, resulting in smoother cutting action and longer tool life.

Those materials used in the construction of spiral flute taps play a critical role in determining their performance and durability. Steel, particularly high-speed steel, cobalt steel, and carbide, are commonly used materials for spiral flute taps due to their excellent wear resistance and toughness. Additionally, coatings such as TiN and TiCN can further enhance the performance of spiral flute taps by reducing friction and heat buildup. By selecting the right material and coating for the specific machining application, manufacturers can ensure that their spiral flute taps deliver optimal performance and longevity.