Why extrusion tap is recognized by the customers

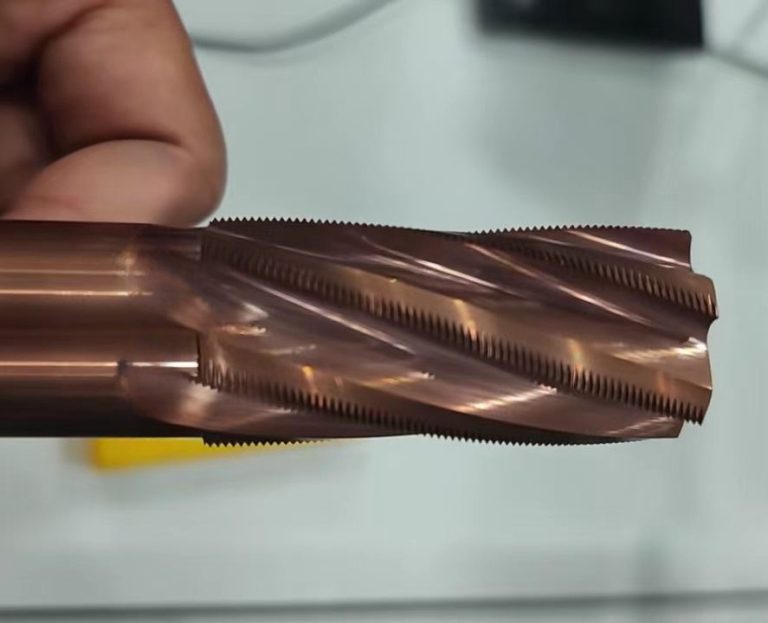

Extrusion taps are a type of cutting tool used in industrial applications to create threads in a variety of materials. These taps are designed to withstand high temperatures and pressures, making them ideal for use in challenging environments. Many manufacturers to machine thread recognize this tool.

The extrusion taps are made from high-quality materials such as high-speed steel or carbide, which allows them to withstand the rigors of industrial use. This durability ensures that extrusion taps can be used repeatedly without losing their cutting ability, making them a cost-effective option for businesses.

Second, extrusion taps are received for their precision. These taps are designed to create threads with tight tolerances, ensuring a secure fit for fasteners and other components. This precision is essential in industries where accuracy is paramount, such as aerospace and automotive manufacturing.

Another advantage of using extrusion taps is their versatility. These taps can be used on a wide range of materials, including metals, plastics, and composites. This versatility makes extrusion taps a valuable tool for businesses that work with a variety of materials in their manufacturing processes.

Extrusion taps are also known for their efficiency. These taps are designed to quickly and easily create threads in materials, reducing the time and labor required for this task. This efficiency can help businesses increase their productivity and meet tight production deadlines.

Most of operators can use extrusion taps easily. These taps can be operated using standard tapping equipment, making them accessible to businesses of all sizes. This ease of use allows businesses to quickly integrate extrusion taps into their manufacturing processes without the need for specialized training or equipment.

Additionally, extrusion taps are environmentally friendly. These taps produce minimal waste during the threading process, reducing the environmental impact of industrial operations. This eco-friendly feature is important for businesses looking to reduce their carbon footprint and operate in a sustainable manner.

Therefore, the advantages of using extrusion taps in industrial applications are clear. Whether you work in aerospace, automotive, or any other industry that requires threading, extrusion taps are a reliable and cost-effective tool that can help you achieve your production goals.