thread milling cutter application

Thread milling cutters are an essential tool in precision machining, offering a range of advantages that make them highly sought after in various industries. These cutters are designed to create threads in a wide range of materials, including metals, plastics, and composites. we will explore the features of thread milling cutters in applications.

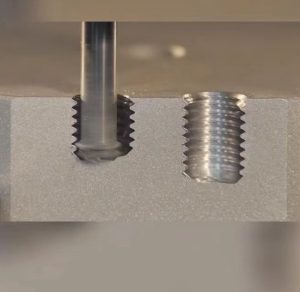

The thread milling cutters is well-adapted. Unlike traditional tapping methods, which require different tools for each thread size, thread milling cutters can create multiple thread sizes with a single tool. This not only saves time but also reduces the need for multiple tools, making the machining process more efficient and cost-effective

thread milling cutters can produce threads with high precision and accuracy. These cutters are designed to create threads with tight tolerances, ensuring that the final product meets the required specifications. This level of precision is crucial in industries such as aerospace and automotive, where even the slightest deviation can have significant consequences.

Furthermore,thread milling cutters also offer excellent chip evacuation capabilities. The design of these cutters allows for the efficient removal of chips during the machining process, preventing chip buildup and reducing the risk of tool breakage. This is particularly important when working with difficult-to-machine materials or when creating deep threads, as chip evacuation becomes more challenging.

In addition to the above characteristics in applications, thread milling cutters also provide excellent surface finish. The cutting edges of these cutters are designed to produce smooth and clean threads, resulting in a high-quality surface finish. This is especially beneficial in applications where aesthetics or surface integrity are critical, such as in the medical or electronics industries.

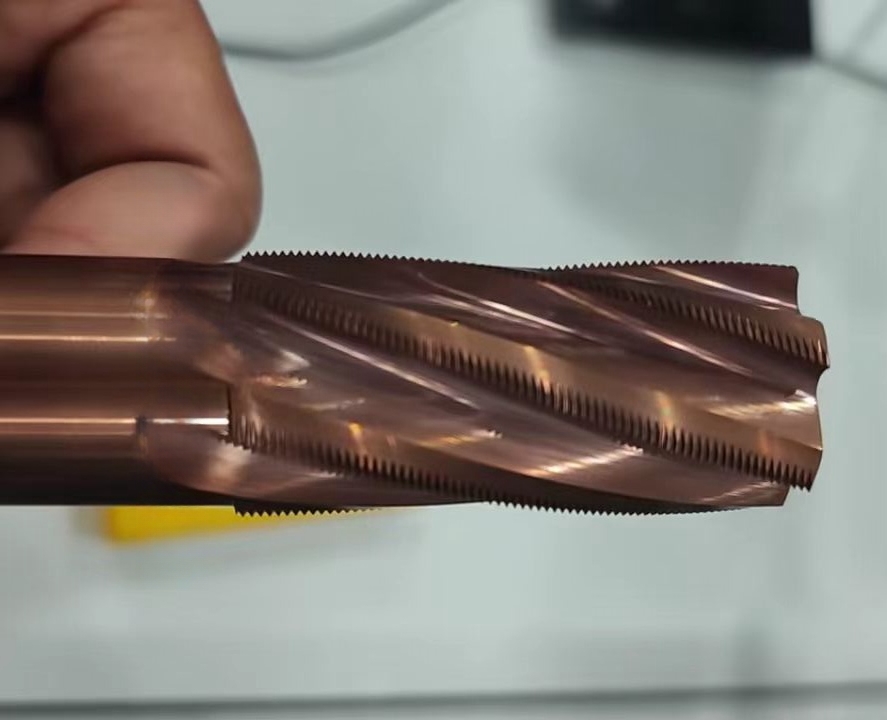

Those cutters offer increased tool life compared to other threading methods. The cutting edges of these cutters are typically made from high-quality materials, such as carbide or high-speed steel, which are known for their durability and wear resistance. This means that thread milling cutters can withstand the demands of high-speed machining and prolonged use, resulting in longer tool life and reduced tooling costs.

Another advantage of using thread milling cutters is their ability to create threads in challenging or unconventional applications. These cutters can be used to create threads in non-standard hole sizes, irregular shapes, or even on curved surfaces. This opens up new possibilities for designers and engineers, allowing them to create innovative and complex components that were previously difficult or impossible to achieve.

thread milling cutters offer a range of advantages to handle challenging applications make them a valuable tool for various industries. Whether it is creating threads in different materials, achieving tight tolerances, or producing high-quality surface finishes, thread milling cutters are a reliable and efficient choice for various applications.