Thread milling cutter definition

Thread milling is a machining process used to produce threads on a workpiece. It involves the use of a thread milling cutter, which is a specialized tool designed for this purpose. we will explore the definition of a thread milling cutter and its role in the thread milling process.

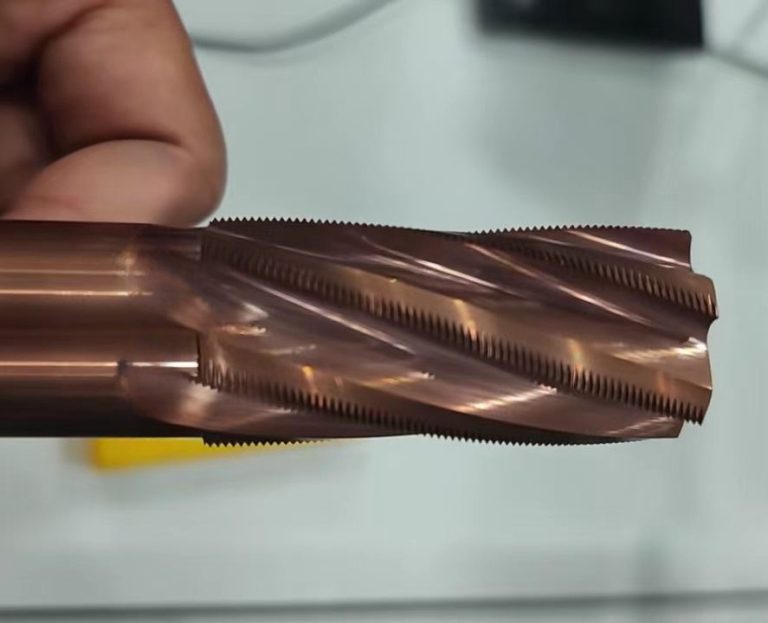

A thread milling cutter is typically made of high-speed steel or carbide and has multiple cutting edges. These cutting edges are arranged in a helical pattern, allowing the cutter to produce threads as it rotates.

The main advantage of using a thread milling cutter is its versatility. Unlike other thread cutting methods, such as tapping or die cutting, thread milling can produce threads of various sizes and pitches. This makes it suitable for a wide range of applications, from small screws to large bolts.

The thread milling cutter is designed to be used in a milling machine, which is a machine tool used for removing material from a workpiece. The milling machine holds the workpiece in place while the cutter rotates and moves along the workpiece to create the desired thread.

To use a thread milling cutter, the milling machine operator must first set up the machine and secure the workpiece. The cutter is then mounted onto the machine’s spindle and positioned above the workpiece. The operator adjusts the machine’s settings, such as the speed and feed rate, to ensure optimal cutting conditions.

Once everything is set up, the operator starts the milling machine, and the cutter begins to rotate. As the cutter moves along the workpiece, it removes material to create the thread. The cutting edges of the cutter engage with the workpiece, removing small chips of material with each rotation.

The thread milling cutter can produce both internal and external threads. For internal threads, the cutter moves into the workpiece, creating a hole with the desired thread profile. For external threads, the cutter moves along the outside of the workpiece, removing material to create the thread.

One of the key advantages of using a thread milling cutter is its ability to produce threads with high precision. The helical arrangement of the cutting edges allows for smooth and accurate cutting, resulting in threads with tight tolerances. This is particularly important in industries where precision is crucial, such as aerospace and automotive manufacturing.

A thread milling cutter is a versatile tool that can create threads of various sizes and pitches. By using a milling machine, the cutter removes material from the workpiece to create the desired thread. With its ability to produce threads with high precision, the thread milling cutter is an essential tool in many industries.