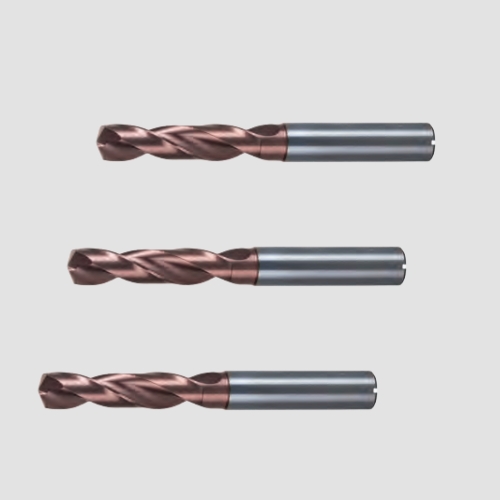

solid carbide drill advantages

Solid carbide drills are widely used in various industries due to their numerous advantages over other types of drills. One of the key benefits of solid carbide drills is their increased durability and longevity. In this section, we will explore why solid carbide drills are known for their exceptional lifespan and how they can outperform other drill types in terms of durability.

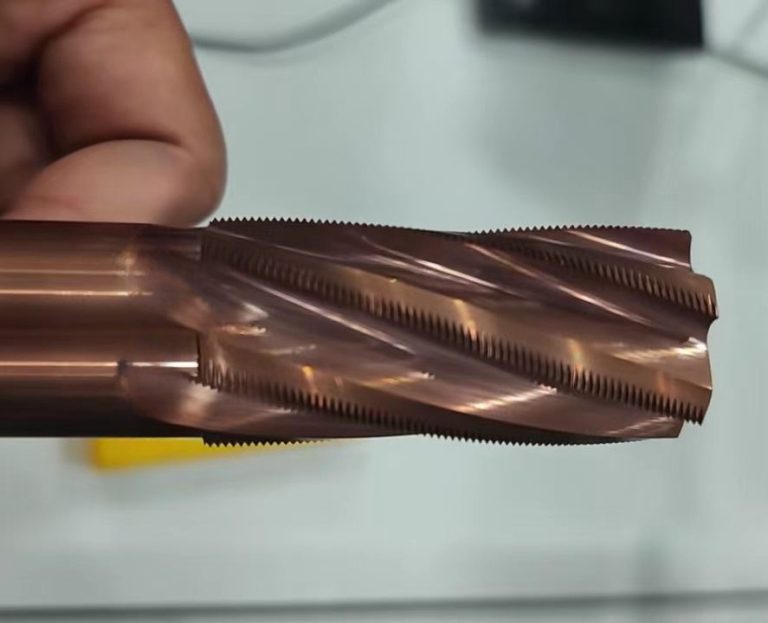

Solid carbide drills are made from a combination of tungsten carbide and cobalt. This unique composition gives them a remarkable hardness and resistance to wear. Unlike high-speed steel drills, which can become dull and lose their cutting edge quickly, solid carbide drills maintain their sharpness for a significantly longer time. This means that they can be used for a prolonged period without the need for frequent replacements, resulting in cost savings for businesses.

Furthermore, solid carbide drills are designed to withstand high temperatures generated during drilling operations. The combination of tungsten carbide and cobalt allows these drills to dissipate heat efficiently, preventing overheating and reducing the risk of tool failure. This heat resistance is particularly crucial when drilling through tough materials such as stainless steel or hardened alloys, where the temperature can rise rapidly. Solid carbide drills excel in such demanding applications, ensuring consistent performance and minimizing downtime.

Another advantage of solid carbide drills is their resistance to chipping and breaking. The hardness of tungsten carbide makes these drills less prone to damage when encountering hard or abrasive materials. This durability is especially beneficial in industries like aerospace or automotive, where precision drilling is essential, and any tool failure can lead to costly rework or delays. Solid carbide drills provide the reliability and stability needed to tackle challenging drilling tasks without compromising on quality.

Moreover, solid carbide drills offer excellent precision and accuracy. Their rigid construction and superior cutting edge retention allow for consistent hole size and shape, ensuring a high level of dimensional accuracy. This is crucial in industries such as medical or electronics, where even the slightest deviation can have severe consequences. Solid carbide drills provide the necessary precision to meet the stringent requirements of these sectors, making them a preferred choice for critical applications.

solid carbide drills also offer increased productivity. Their exceptional cutting performance allows for faster drilling speeds and higher feed rates, resulting in reduced cycle times. This improved efficiency translates into higher productivity and cost savings for businesses. Moreover, the extended tool life of solid carbide drills means less time spent on tool changes, further enhancing productivity and reducing downtime.

solid carbide drills offer numerous advantages over other drill types, particularly in terms of durability and longevity. Their unique composition of tungsten carbide and cobalt provides exceptional hardness, heat resistance, and resistance to chipping and breaking. These qualities make solid carbide drills ideal for demanding applications and industries where precision and reliability are paramount. Additionally, their superior cutting performance and extended tool life contribute to increased productivity and cost savings. Overall, solid carbide drills are a reliable and efficient choice for any drilling operation.