The Advantages of Using a Thread Forming Tap–

Thread forming tap Vs Cutting tap

Thread forming taps and cutting taps are two common types of taps used in the manufacturing industry. While both serve the purpose of creating internal threads in a workpiece, they differ in their approach and the advantages they offer. In this article, we will explore the advantages of using a thread forming tap over a cutting tap.

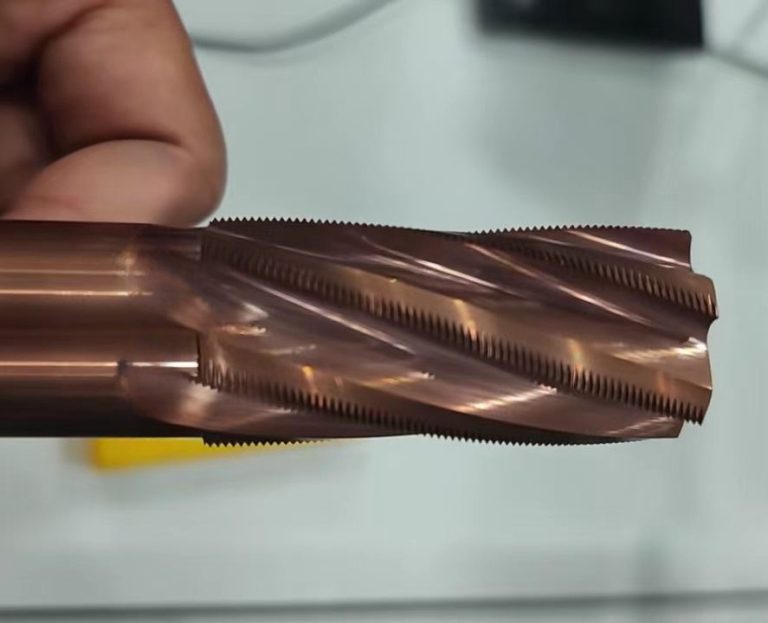

One of the main advantages of using a thread forming tap is its ability to produce stronger threads. Unlike cutting taps that remove material to create threads, thread forming taps work by displacing the material. This displacement causes the material to flow into the shape of the tap, resulting in a thread that is more resistant to stripping and pulling out. This makes thread forming taps ideal for applications where thread strength is crucial, such as in aerospace or automotive industries.

Another advantage of thread forming taps is their ability to create threads in difficult-to-machine materials. Cutting taps often struggle with materials that are prone to work hardening or have high tensile strength. In contrast, thread forming taps excel in these situations. By displacing the material rather than cutting it, thread forming taps can create threads in materials that would otherwise be challenging to tap. This makes them a preferred choice for working with materials like stainless steel or titanium.

Thread forming taps also offer improved chip control compared to cutting taps. When using a cutting tap, chips are generated as the material is removed. These chips can cause issues such as chip clogging or damage to the tap. In contrast, thread forming taps produce chips that are smaller and more manageable. The reduced chip size allows for better chip evacuation, resulting in smoother and more efficient tapping operations. This is particularly beneficial when working with materials that tend to produce long, stringy chips.

Additionally, thread forming taps are known for their longer tool life. Since they do not remove material like cutting taps, thread forming taps experience less wear and tear. This leads to a longer lifespan for the tap, reducing the need for frequent tool changes and increasing productivity. The extended tool life also translates to cost savings for manufacturers, as they can achieve more taps per tool before replacement is necessary.

Furthermore, thread forming taps offer improved thread quality. The displacement of material during the tapping process results in threads with a higher degree of accuracy and consistency. This is especially important in applications where precise thread fit is required, such as in the medical or electronics industries. The improved thread quality achieved with thread forming taps ensures a tighter and more reliable connection between components.

The advantages of using a thread forming tap over a cutting tap are numerous. From producing stronger threads to working with difficult materials, thread forming taps offer a range of benefits. Their improved chip control, longer tool life, and superior thread quality make them a preferred choice for many manufacturing applications. By understanding the advantages of thread forming taps, manufacturers can make informed decisions when selecting the appropriate tapping method for their specific needs.