type of machine taps

Exploring the Different Types of Machine Taps and Their Uses

Machine taps are a type of cutting tool used to create internal threads in a pre-drilled hole. They are used in a variety of applications, from automotive and aerospace engineering to plumbing and electrical work. There are several different types of machine taps available, each designed for a specific purpose. In this article, we will explore the different types of machine taps and their uses.

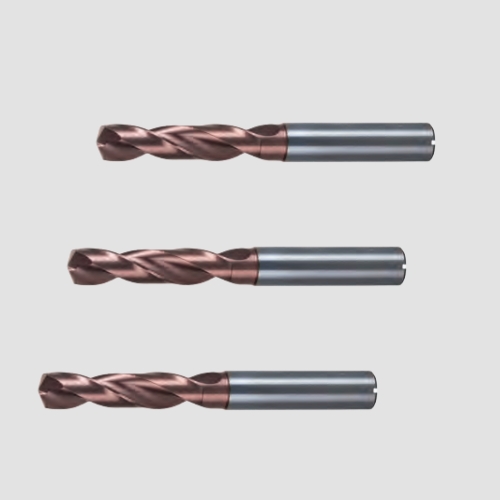

The most common type of machine tap is the taper tap. This type of tap has a tapered end that gradually increases in diameter as it is inserted into the hole. It is used to create threads in softer materials such as aluminum and brass.

The second type of machine tap is the plug tap. This type of tap has a straight flute and is used to create threads in harder materials such as steel and stainless steel. It is also used to create threads in pre-drilled holes that are too small for a taper tap.

The third type of machine tap is the bottoming tap. This type of tap has a straight flute and is used to create threads in pre-drilled holes that are too small for a plug tap. It is also used to create threads in blind holes, which are holes that do not go all the way through the material.

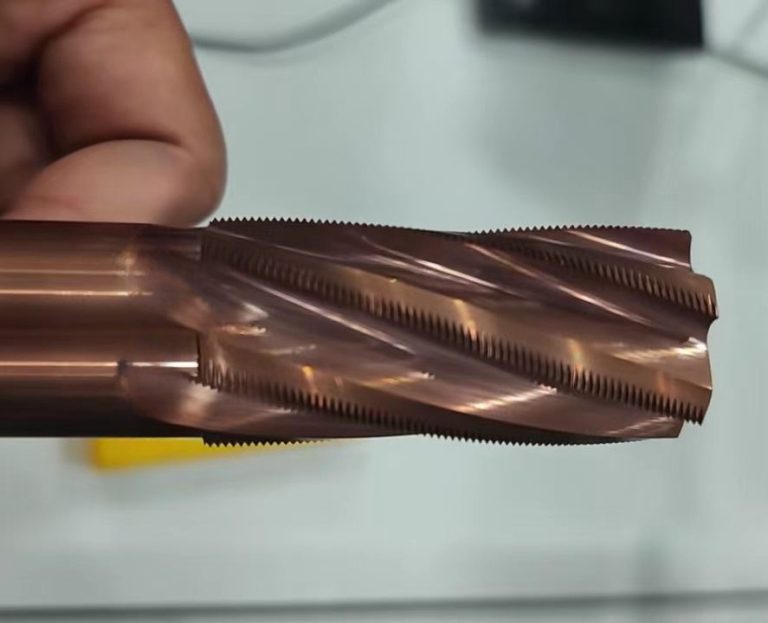

The fourth type of machine tap is the spiral point tap. This type of tap has a spiral flute and is used to create threads in materials that are too hard for a plug or bottoming tap. It is also used to create threads in blind holes.

Finally, the fifth type of machine tap is the spiral flute tap. This type of tap has a spiral flute and is used to create threads in materials that are too hard for a plug or bottoming tap. It is also used to create threads in blind holes.

In conclusion, there are five different types of machine taps available, each designed for a specific purpose. Taper taps are used to create threads in softer materials, while plug taps are used to create threads in harder materials. Bottoming taps are used to create threads in pre-drilled holes that are too small for a plug tap, and spiral point and spiral flute taps are used to create threads in materials that are too hard for a plug or bottoming tap. be cut. For example, a straight flute tap should be used for cutting straight threads, while a spiral flute tap should be used for cutting tapered threads.