the factors of machine tap selection

Exploring the Different Types of Machine Taps and How to Choose the Right One for Your Application

When it comes to machining, taps are essential tools for creating internal threads in a variety of materials. Taps come in a variety of shapes and sizes, and each type is designed for a specific application. Understanding the different types of taps and how to choose the right one for your application is essential for achieving the best results.

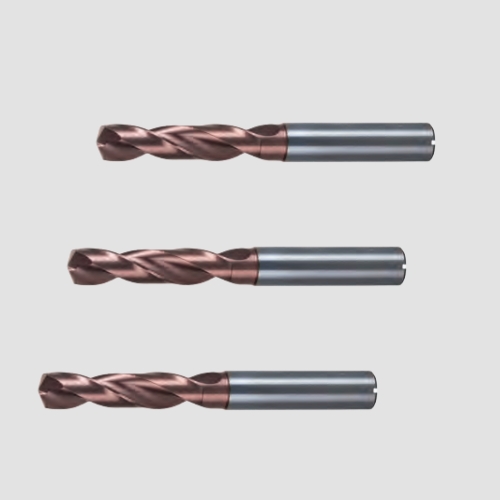

The most common type of tap is the straight flute tap. This type of tap is designed for general-purpose applications and is suitable for most materials. It is the most economical option and is available in a variety of sizes and pitches.

Another type of tap is the spiral flute tap. This type of tap is designed for cutting harder materials and is more efficient than the straight flute tap. It is also more expensive and is available in a variety of sizes and pitches.

The third type of tap is the spiral point tap. This type of tap is designed for cutting through tough materials and is the most efficient of all the taps. It is also the most expensive and is available in a variety of sizes and pitches.

The fourth type of tap is the taper tap. This type of tap is designed for creating internal threads in a variety of materials. It is the most expensive of all the taps and is available in a variety of sizes and pitches.

When choosing the right tap for your application, it is important to consider the material you are working with, the size and pitch of the thread, and the type of tap you need. It is also important to consider the cost of the tap and the quality of the tap.

Understanding the Factors That Impact Machine Tap Selection: Material, Thread Pitch, and More

When selecting a machine tap for a specific application, there are several factors to consider. These include the material being tapped, the thread pitch, the tap size, the tap type, and the tap geometry. Understanding the impact of each of these factors on the selection process is essential for ensuring the right tap is chosen for the job.

The material being tapped is one of the most important factors to consider when selecting a machine tap. Different materials require different types of taps, as some materials are harder than others and require more aggressive cutting edges. For example, taps designed for use on aluminum are typically made from high-speed steel, while taps designed for use on stainless steel are usually made from cobalt or carbide.

The thread pitch is another important factor to consider when selecting a machine tap. That is the distance between the threads on the tap, and it must match the thread pitch of the material being tapped. If the thread pitch is too large, the tap will not cut properly, and if it is too small, the tap will not fit properly.

The tap size is also an important factor to consider when selecting a machine tap. The tap size is determined by the diameter of the hole being tapped, and it must match the size of the material being tapped. If the tap size is too large, the tap will not fit properly, and if it is too small, the tap will not cut properly.

The type of tap is also an important factor to consider when selecting a machine tap. Different types of taps are designed for different applications, and the type of tap must match the application. For example, spiral point taps are designed for cutting through tough materials, while bottoming taps are designed for creating threads in blind holes.

The tap geometry is also an important factor to consider when selecting a machine tap. Different types of taps have different geometries, and the geometry must match the application. For example, straight flute taps are designed for general-purpose applications, while spiral flute taps are designed for cutting through tough materials.

By understanding the factors that impact machine tap selection, it is possible to ensure the right tap is chosen for the job. The material being tapped, the thread pitch, the tap size, the tap type, and the tap geometry must all be taken into account when selecting a machine tap. With the right information, it is possible to make an informed decision and ensure the right tap is chosen for the job.